PROCESSES

01. LARVICULTURE

02. SHRIMP FARMING

03.HARVEST

04. Raw material reception and analysis

05. Selection process

06. Ranking

07. ADDED VALUE

08. PACKAGING – CASES

09. FREEZING

This technique consists of spraying the surface of the product with water in order to generate a thin film of ice quickly and individually.

10. PACKAGING – MASTER

11. STORAGE

12. EXPORT

01.LARVICULTURE

Larviculture corresponds to the first stage of development of the animal before it becomes a shrimp. It consists of 4 stages: nauplius, zoea, mysis and postlarva, and each of these stages contains phases that mark the body development of the specimens. This is the stage where the necessary conditions are created for the culture and maintenance of the larvae, with the purpose of increasing survival levels..

02. SHRIMP FARMING

Once the post-larvae stages are reached, they are transferred to small ponds called nurseries or nurseries, where they are placed in densities of up to 150 animals/m2 . When they weigh between 1 and 3 grams, the shrimp are transferred to larger fattening tanks (between 3 and 16 ha), where they remain until they reach the planned commercial size.

03. HARVEST

The shrimp harvesting process begins with pre-harvest sampling, which consists of identifying which ponds will be in the harvesting program. This activity begins with sampling to determine the size distribution, product quality, and quantity of shrimp to be harvested. The product is taken live to the pre-processing plant, where it is separated from any element that is foreign to the shrimp, and immediately loaded onto ice bins, which are transported to our processing plant..

04. Reception and

raw material analysis

The harvested raw shrimp is transported to our plant, which is unloaded through baskets with ice at temperatures ranging between zero and ten degrees. This activity includes all the necessary inspection controls to ensure the freshness conditions, free of contamination, odors and strange flavors of our shrimp..

05. Selection process

The shrimp are placed on conveyor belts, from which shrimp that do not meet the requirements to be first class or for export, i.e., broken, stained shrimp that are altered in their organic constitution, are removed. This selection process is supervised by trained and qualified personnel..

06. Ranking

This is done by means of sorting machines, which have an integrated system of hoppers and conveyor belts that allow the shrimp to be correctly sorted by size and then weighed and packaged..

07. ADDED VALUE

It consists of special cuts made to the shrimp, apart from the removal of the head. Among the most common value-added products are: PUD (peeled with vein), P&D (peeled and deveined), PPV: (peeled and deveined with need

08. PACKAGING – CASES.

The products are sent to the packing tables, where they are packed, weighed and glazed. Normally we work with our brand AGROLAGO, but we can also work with customer’s brands or with generic packaging.

09. FREEZING

The freezing process is carried out by the company through two mechanisms, the first through forced air, this freezing system uses small cold rooms known as tunnels, which by means of evaporators are responsible for freezing large volumes of packaged shrimp in an average time of 12 hours. The second process is the INDIVIDUAL QUICK FREEZING SYSTEM – IQF. This technique consists of spraying the surface of the product with water in order to generate a thin film of ice quickly and individually..

10. PACKAGING – MASTER

After freezing, the cases are packed in 4 or 5 pounds or Kg packages depending on the export market, these packages or Masters are secured with strapping or adhesive tapes to give consistency and safety in handling. We usually work with our brand AGROLAGO, but we can also work with customer’s brands or generic packaging.

11. STORAGE

When the product is properly frozen, it is taken to preservation cellars, which keep the product at an average temperature of -18ºC, in order to preserve the product to be exported later.

12. EXPORT

Complying with all the existing regulations and protocols, the company carries out the respective procedures for the shipment of the order to the customer abroad. This activity is delegated to our customs agent who guarantees the timely fulfillment of our commitment with the client..

– JACK WELCH

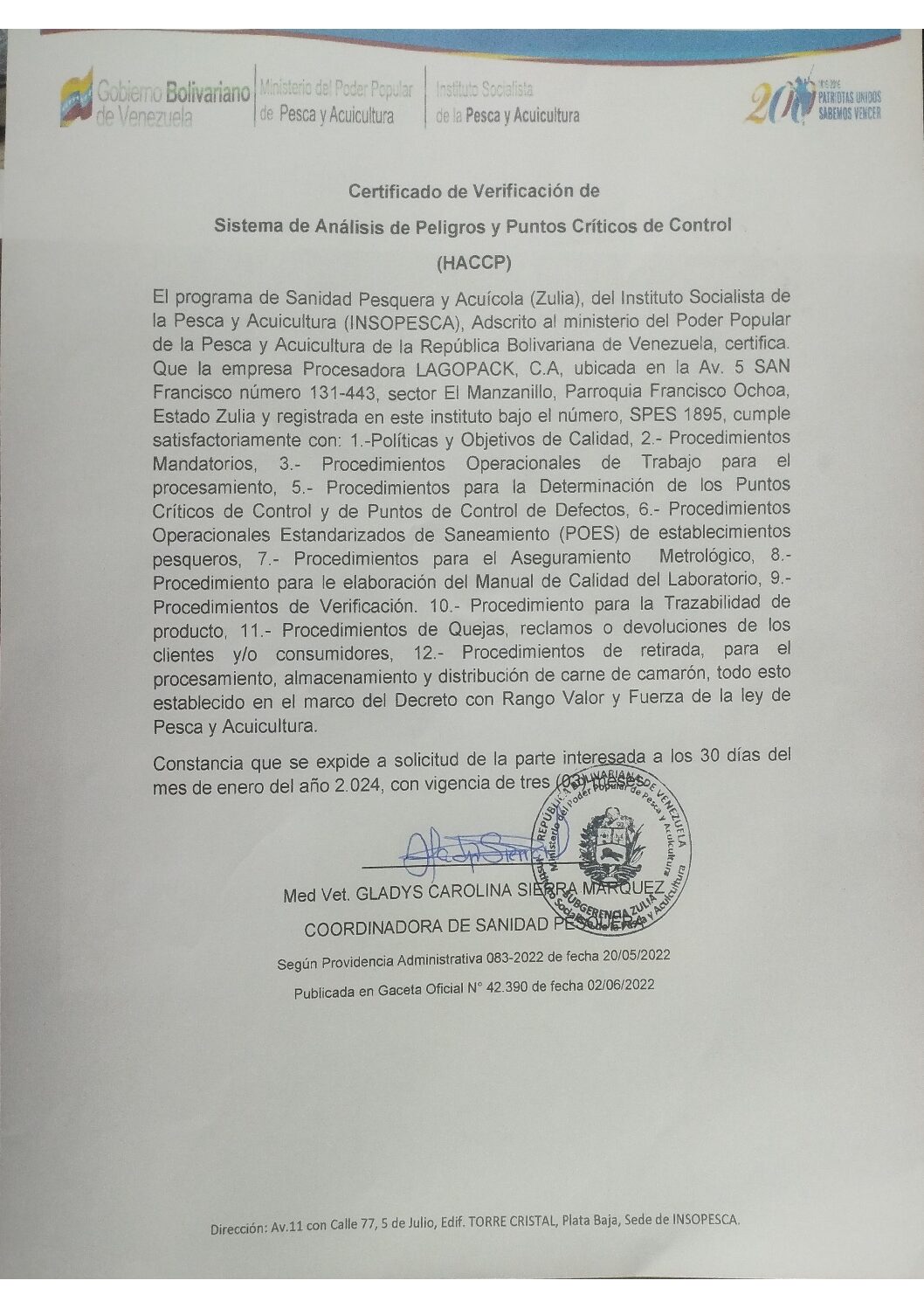

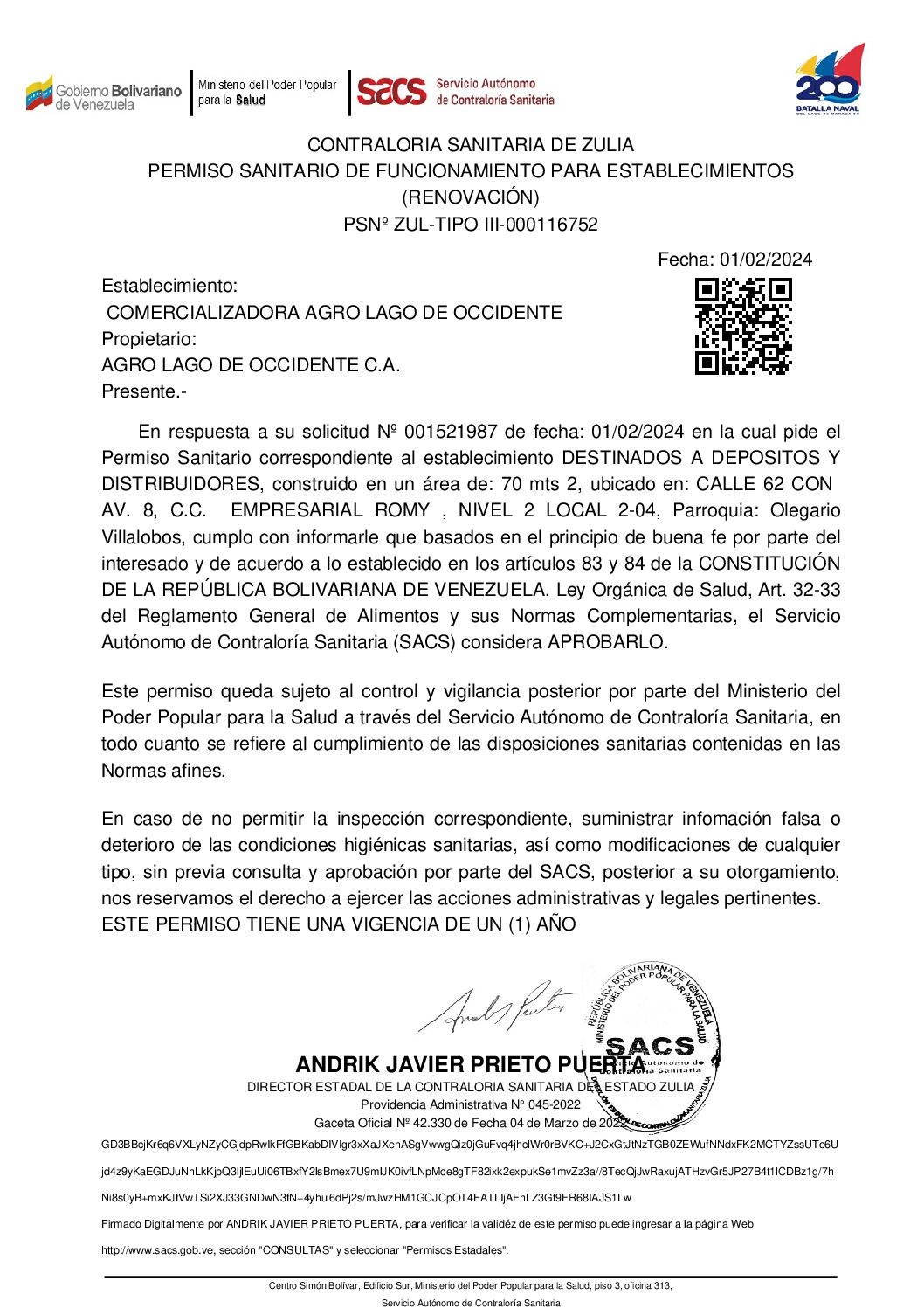

QUALITY MANAGEMENT SYSTEM

All our processes maintain a rigorous quality control that assures the legality, quality and traceability of our products, in order to achieve customer satisfaction.

Our Quality Policy has been the organization’s line of action to improve its internal processes and from the beginning has guaranteed the safety and innocuousness of our products.

Our processes have been developed under national and international standards and have a Traceability Plan that gathers all the activities that are developed in the company and that allow us to reconstruct the history of the products at a given time.

These protocols have an Identification System that provides information as follows:

BACKWARD TRACEABILITY IDENTIFICATION SYSTEM

It allows us to know precisely the origin of the raw material, through the collection of systematic information stored in our database at the time of receipt, so that we can know in a timely manner the data on the supplier, date of entry, quantity and any other data deemed necessary.

The reception of raw materials and their identification is a key and necessary factor for products to be traced back to their origin, i.e. to any point in their previous stage.

INTERNAL TRACEABILITY IDENTIFICATION SYSTEM

Internal traceability can be the most complex and must relate exhaustively to the manufactured product with certain data such as: Identification of the final product, and of the process by means of a code corresponding to the batch. Registration of the date of the manufacturing process of the product, among others.

QUALITY POLICY

AGROLAGO DE OCCIDENTE, C.A. within the framework of its vision and mission, is committed to:

- Comply with the requirements of customers and interested parties, periodically measuring the level of satisfaction achieved.

- Investigate and understand the needs of the customer and relevant interested parties, in order to be able to anticipate their expectations.

- Continuously improve staff competencies, physical resources and the Quality Management System, to ensure compliance with customer requirements and try to exceed their expectations while maintaining an appropriate balance between all stakeholders.

• Desarrollar una cultura de la Calidad que sea compartida por los miembros de AGROLAGO y sus principales partes interesadas.

![FL_20221129212217_CUP-C-865771-MSC-01-2022[R][R]](https://agrolago.com/wp-content/uploads/2021/03/FL_20221129212217_CUP-C-865771-MSC-01-2022RR-pdf.jpg)